The chain is an important component of the chain conveyor, because the type of conveyor is different, so the device used to drive the operation of the Coupling chains is also different. In the design, it is necessary to fully grasp the difference between it and the transmission chain, and the effect of Coupling chains can be fully played.

Because the speed of the drive motor in the conveyor is much higher than the Coupling chains operating speed requirements, so the chain conveyor must have a deceleration mechanism, so when the mechanical speed control Coupling chains operating speed needs to change within a certain range, it can not only be achieved by motor speed regulation.

The correct design of chain conveyor must pay attention to the difference between Coupling chains and transmission chains, although the two may sometimes be very similar in structure, or even exactly the same, but the function of the two is clearly different, can not be generalized.

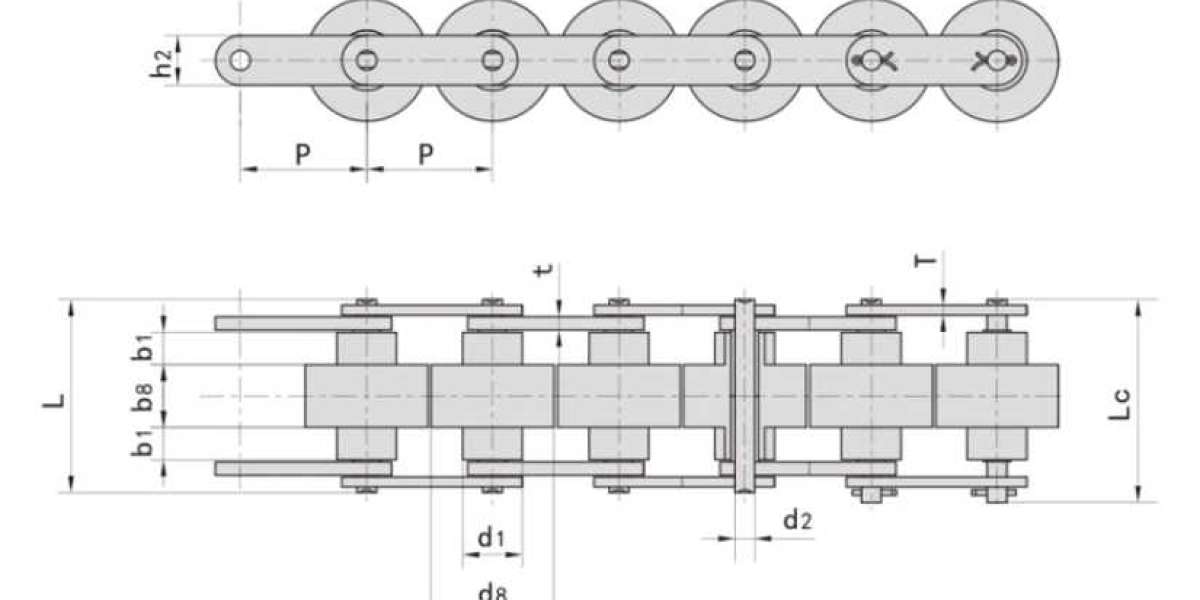

Coupling chains need to have the function of carrying items and running on the track. Therefore, further correct analysis of the Coupling chains force and its force flow distribution is required, which plays a key role in the rationality of its design.

In order to enable the Coupling chains to be kept in a certain tensioning state, a corresponding tensioning device is also required to eliminate the phenomenon of jumping, vibration and abnormal noise during the operation of the chain conveyor due to the relaxation of the chain. When the Coupling chains are extended due to wear, they can also be compensated by tensioning devices to maintain the chain's pretightness.

From this point of view, the tension device is also one of the indispensable conditions for the normal operation of the Coupling chains. Without it, the chain is likely to have a series of failures, which directly affects the working state of the entire chain conveyor.

Coupling chains https://www.qj-chain.com/Coupling-chain.html